Multiple Anomalies Detected In Silver ETFs

Tyler Durden of Zero Hedge has posted an analysis of SLV's bar list by "Project Mayhem Research" (PMR for short) that concludes:

During our research into the inventory lists of the iShares SLV and London-based ETFS physical silver funds, we discovered multiple anomalies which cannot be easily dismissed. These included the presence of internal duplicates, rough internal duplicates, weight duplicates, statistical clustering, and cross-reference duplicates.

It would probably have helped perceptions of impartiality if PMR hadn’t made references to "world silver price management and a functional oligopoly for the elite" and “one might expect Western governments and megabanks to be openly hostile towards silver” in their introduction, but I suppose in these times it is best if one is transparent about one’s biases. In that spirit, I should point out that as an employee of the Perth Mint, the gold and silver ETFs are competitors of our Depository facility so it would be in my/our commercial interests for SLV or GLD to be revealed as a scam.

Unfortunately, I operate under the ethic of reciprocity, otherwise known as "do unto others as you would have others do unto you" so I'll have to be fair and factual in my analysis of this analysis. This may mean that, shock horror, I say some things in defence of SLV.

At this time I would also like to issue a warning that what follows is some technical nit picking probably only of interest to myself, PMR and a few other nerds, done on the basis that the PMR analysis is a working paper. If this sounds a bit too boring, and you are of a conspiracy bent, may I suggest this article to reinforce your prejudices. For those who think gold and silver “enthusiasts” are nutters, you’ll find this article more to your liking.

Firstly, it is worth noting the London Bullion Market Association’s (LBMA) delivery standards for 1000oz silver bars, as this is the standard to which the bars on the lists have been produced:

Minimum weight: 750 troy ounces

Maximum weight: 1100 troy ounces

Minimum purity: 99.9%

Weight rounding: rounded down to the nearest 0.10 of a troy ounce

Marks:

* Brand

* Serial Number

* Year of Manufacture

* Purity

* Weight (optional on the bar but not on the bar list of course)

PMR makes reference to a choice of “primary key”, in other words, how does one uniquely identify a bar? I think it would be obvious to most that Brand and Serial Number together are needed, as we cannot assume that each manufacturer uses a totally unique numbering range or system.

However, it is crucial to note that many manufacturers restart serial numbers each year. By way of explanation, I quote from a letter dated 8 Dec 2004 from Johnson Matthey to the World Gold Council:

I am writing to confirm the marking protocol for Johnson Matthey Good Delivery Gold bars produced in the UK. Prior to 2002 all bars were stamped with a two letter code and number, i.e:– BT 12345 for a bar produced in 1999, CT 12345 for a bar produced in 2000. Therefore, some bars will have the same numbers but with different Pre-Fixes. Both the letter AND number combination need to be taken into account to identify the bar. After 2002 we moved to a year stamp i.e. 2003 and a number sequence.

This means that we must ensure a year designator is included along with the Brand and Serial Number in our Primary Key. In the case of the pre-2003 Johnson Matthey gold bars, the inclusion of the two letter prefix performs this function for us; for post-2002 bars, we would have to ensure there is a year prefix in the serial number.

Now this is where we come into a problem. A scroll through the 7000+ page SLV bar list reveals many occurrences of the same Brand and Serial Number but different weight (see page 509 for an example). The different weight implies that these are different bars and that the person originally recording the bar’s details failed to include the year prefix (either as letters or the actual year) in the serial number or as a separate field in the bar list. This means we are unable to conclusively create a unique identifier.

I would note at this point that it is necessary to know which manufacturers restart serial numbers each year and also their serial number/ marking protocol. This is the only way to know if a serial number we see for a bar on a listing is complete or is missing the year prefix.

As an alternative to contacting each manufacturer for their serial numbering protocol, I would suggest combining all published silver bar listings and then analysing for what PMR calls “Internal Duplicates” (common Brand and Serial Number). Manufacturers with no restarting policy would show no (or few, if you’re expecting fraud) duplicate serial numbers. Those with many duplicate serial numbers and differing weights would imply a restarting policy (Britannia Refined Metals is one clear example). Further analysis may reveal patterns in the serial numbering enabling confidence which part of the serial number represents the year.

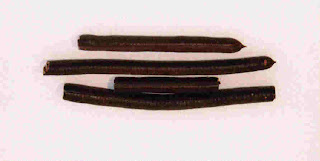

At this point I would also make a small point about human error. In the last audit of GLD Inspectorate International Ltd did a random check of 7772 bars out of a total of 88445. They found 22 bars with incorrectly recorded serial numbers (a 0.28% error rate). I quote this not to make excuses, but as a reminder there is such a thing as human error. In a case of duplication we must therefore consider the possibility of recording error. What is a reasonable error rate can be debated, but I would note that in the surface finish of 1000oz silver bars can be heavily pitted, resulting in digits of the serial number or weight not stamping clearly. In my previous roles in the Perth Mint I have done many stocktakes and can confirm that the quality of some manufacturers leaves a lot to be desired and have had some difficultly confirming bar markings.

Given the above, for those manufacturers with no restarting policy, one can confidently use a Primary Key composed of Brand and Serial Number only. Therefore I would suggest that PMR first needs to prove/establish which manufacturers have no restarting policy. Then, if they find the existence of an identical weight for such branded bars, they have clear proof of a duplicate, or double counting.

The rest of the discussion below focuses on those manufacturers with a restarting policy. In this case one first has to look at the recording accuracy of the serial numbers. A cursory look at the SLV list reveals that Britannia Refined Metals, Cominco Ltd Tadanac Canada and Russian State Refineries operate under a restarting policy due to the existence of many duplicate serial numbers with different weights. Therefore, for these manufacturers the occurrence of a duplicate serial numbers with the same weight is not conclusive proof of itself that we have a duplicate bar, as the serial number may be incorrectly recorded.

As a result, I do not feel that PMR’s "Perfect Internal Duplicate" (identical brand, serial number and weight) rate of 0.0242% for SLV (69 bars out of 285479) is not conclusively proven at this stage. I would note that removing the three manufacturers mentioned above brings this duplication rate down to 11 bars.

One way around the problem of restarted serial numbers, but incomplete recording of year to distinguish duplicated serial numbers for a manufacturer, is (apart from custodians producing a decent/detailed bar list to start with) to look at the frequency of what PMR calls “Rough Internal Duplicates” (identical brand and weight with an almost-identical serial number (eg AB1024 vs 1024). Effectively this is the process of stripping out the year identifier from the serial number so that all serial numbers for that manufacturer are on “equal footing”, so to speak.

PMR makes reference to the technique of removing prefixes in this comment and this comment. But for this to be valid PMR must first prove/establish which manufacturers restart their serial numbers each year and then their serial number/ marking protocol. If for a certain manufacturer the prefix is not a year designator but just part of the sequential serial number, then removing it creates false duplications. It would be the same as removing the first digit from identical weighted bars with serial numbers 1234 and 2234 and concluding they are the same bar.

It is worth noting at this time that the LBMA standards round down actual weights to the nearest 0.10 of a troy ounce. This means that two bars with a reported (bar listing weight) of 1001.1 could actually be two different bars with weights of 1001.11 and 1001.19 when put on scales. This complicates things so lets park this to the side for now.

PMR notes that “To find the same manufacturer with an identical bar weights is not unusual, but beyond some expected statistical occurance it is”. This statement depends on one crucial assumption – the normal distribution of bar weights. As PMR says, “If these exceed what would be predicted by the Gaussian bell curve, one explanation which may be considered is bar ‘cloning’”. I would caution here that normal distributions assume random variables.

Remember that the LBMA standards accept bars with weights between 750 troy ounces and 1100 troy ounces. The reason for this is that is make manufacture of the bars cheaper as one does not have to accurately weigh out granules/shot of silver for each bar – these are industrial wholesale bars after all.

The minimum of 750 is in reality too low and in my experience the distribution of weights is not so wide. One commentator has noted that “there seem to be two categories of weights, one with target weight of 970 oz., the other one 1030 oz”, which does not surprise me. The point I would like to make is that I think a proper statistical analysis of the weight distributions will show that they are not normally distributed and have a material amount of skewness and peaks around certain weights.

To understand why this is the case, consider that pouring bars is much like making cupcakes or muffins. You have standardises moulds in which you pour your cake mixture. One can expect that first time cooks will put too much or too little in, and their resulting muffins are too big or too small. However, over time one builds up skill to the point that we would observe that each muffin is very much the same size.

There is no difference with pouring bars. If you have an experienced pourer, you can expect that they sequence of bars they pour have little variation in weight. You can also expect that some pourers err on the side of underweight bars (too much and the silver may spill on the floor) whereas other more experienced pourers are confident with attempting to fill the mould. If you had an entire sequence of serial numbers, you may also find a group where the bar weights are all over the place – this being when the apprentice pourer had their first go. Wide bar weights could also indicate a workplace where the staff don’t have any pride in their job, so don’t care about accuracy, or maybe where the expected work rate is high so it is not possible to be accurate.

The result is that even within manufacturers their may be significant variances in what constitutes a “normal distribution” of bar weights. I am sure statisticians have ways around this, and PMR needs to get a bit more sophisticated in this regard if it is to make a conclusive case.

Finally, I’d like to make some comments on the three other types of duplicates PMR referred to in their analysis.

Weight Duplicate (brand and weight): Of itself, this is the most useless of the duplicates. Considering the weight variances discussed above, it is inevitable that for any manufacturer over many years of production there will be many duplications of weight. The real use of this is to establish the distribution of weights (histogram) for a manufacturer as a basis against which to check whether an observed frequency of duplicate weights is “normal”.

Internal Duplicate (serial number and brand): Given that some manufacturers restart numbering each year, the lack of a year designator (either as letter prefix or year incorporated into the serial number) means that this duplicate is of no use in proving double counting. It is clear from the Britannia bars (see page 509 of the SLV listing) where there are many occurrences of duplicate serial numbers (but different weights) that the year or year prefix has been left off the bar listing. This use of this duplicate is in determining which manufacturers restart serial numbering and which do not.

Cross Reference Duplicate (brand and serial number on two different ETFs): Again, because we have established that serial numbers are not consistently incorporating the year of manufacture, this duplication is not conclusive proof. For those manufacturers with restarting serial numbers, you also need the addition of weight. I would also note that both lists are not issued at the same time: ETFS bar list is dated 29 July 2009 whereas SLV bar list is dated 24 July 2009, which does allow for the fact that bars redeemed by market makers out of one ETF could have been reallocated to the other ETF (note that both ETFs store their metal in London and allow for sub-custodians, so it is possible that one custodian holds bars for both ETFs).

During our research into the inventory lists of the iShares SLV and London-based ETFS physical silver funds, we discovered multiple anomalies which cannot be easily dismissed. These included the presence of internal duplicates, rough internal duplicates, weight duplicates, statistical clustering, and cross-reference duplicates.

It would probably have helped perceptions of impartiality if PMR hadn’t made references to "world silver price management and a functional oligopoly for the elite" and “one might expect Western governments and megabanks to be openly hostile towards silver” in their introduction, but I suppose in these times it is best if one is transparent about one’s biases. In that spirit, I should point out that as an employee of the Perth Mint, the gold and silver ETFs are competitors of our Depository facility so it would be in my/our commercial interests for SLV or GLD to be revealed as a scam.

Unfortunately, I operate under the ethic of reciprocity, otherwise known as "do unto others as you would have others do unto you" so I'll have to be fair and factual in my analysis of this analysis. This may mean that, shock horror, I say some things in defence of SLV.

At this time I would also like to issue a warning that what follows is some technical nit picking probably only of interest to myself, PMR and a few other nerds, done on the basis that the PMR analysis is a working paper. If this sounds a bit too boring, and you are of a conspiracy bent, may I suggest this article to reinforce your prejudices. For those who think gold and silver “enthusiasts” are nutters, you’ll find this article more to your liking.

Firstly, it is worth noting the London Bullion Market Association’s (LBMA) delivery standards for 1000oz silver bars, as this is the standard to which the bars on the lists have been produced:

Minimum weight: 750 troy ounces

Maximum weight: 1100 troy ounces

Minimum purity: 99.9%

Weight rounding: rounded down to the nearest 0.10 of a troy ounce

Marks:

* Brand

* Serial Number

* Year of Manufacture

* Purity

* Weight (optional on the bar but not on the bar list of course)

PMR makes reference to a choice of “primary key”, in other words, how does one uniquely identify a bar? I think it would be obvious to most that Brand and Serial Number together are needed, as we cannot assume that each manufacturer uses a totally unique numbering range or system.

However, it is crucial to note that many manufacturers restart serial numbers each year. By way of explanation, I quote from a letter dated 8 Dec 2004 from Johnson Matthey to the World Gold Council:

I am writing to confirm the marking protocol for Johnson Matthey Good Delivery Gold bars produced in the UK. Prior to 2002 all bars were stamped with a two letter code and number, i.e:– BT 12345 for a bar produced in 1999, CT 12345 for a bar produced in 2000. Therefore, some bars will have the same numbers but with different Pre-Fixes. Both the letter AND number combination need to be taken into account to identify the bar. After 2002 we moved to a year stamp i.e. 2003 and a number sequence.

This means that we must ensure a year designator is included along with the Brand and Serial Number in our Primary Key. In the case of the pre-2003 Johnson Matthey gold bars, the inclusion of the two letter prefix performs this function for us; for post-2002 bars, we would have to ensure there is a year prefix in the serial number.

Now this is where we come into a problem. A scroll through the 7000+ page SLV bar list reveals many occurrences of the same Brand and Serial Number but different weight (see page 509 for an example). The different weight implies that these are different bars and that the person originally recording the bar’s details failed to include the year prefix (either as letters or the actual year) in the serial number or as a separate field in the bar list. This means we are unable to conclusively create a unique identifier.

I would note at this point that it is necessary to know which manufacturers restart serial numbers each year and also their serial number/ marking protocol. This is the only way to know if a serial number we see for a bar on a listing is complete or is missing the year prefix.

As an alternative to contacting each manufacturer for their serial numbering protocol, I would suggest combining all published silver bar listings and then analysing for what PMR calls “Internal Duplicates” (common Brand and Serial Number). Manufacturers with no restarting policy would show no (or few, if you’re expecting fraud) duplicate serial numbers. Those with many duplicate serial numbers and differing weights would imply a restarting policy (Britannia Refined Metals is one clear example). Further analysis may reveal patterns in the serial numbering enabling confidence which part of the serial number represents the year.

At this point I would also make a small point about human error. In the last audit of GLD Inspectorate International Ltd did a random check of 7772 bars out of a total of 88445. They found 22 bars with incorrectly recorded serial numbers (a 0.28% error rate). I quote this not to make excuses, but as a reminder there is such a thing as human error. In a case of duplication we must therefore consider the possibility of recording error. What is a reasonable error rate can be debated, but I would note that in the surface finish of 1000oz silver bars can be heavily pitted, resulting in digits of the serial number or weight not stamping clearly. In my previous roles in the Perth Mint I have done many stocktakes and can confirm that the quality of some manufacturers leaves a lot to be desired and have had some difficultly confirming bar markings.

Given the above, for those manufacturers with no restarting policy, one can confidently use a Primary Key composed of Brand and Serial Number only. Therefore I would suggest that PMR first needs to prove/establish which manufacturers have no restarting policy. Then, if they find the existence of an identical weight for such branded bars, they have clear proof of a duplicate, or double counting.

The rest of the discussion below focuses on those manufacturers with a restarting policy. In this case one first has to look at the recording accuracy of the serial numbers. A cursory look at the SLV list reveals that Britannia Refined Metals, Cominco Ltd Tadanac Canada and Russian State Refineries operate under a restarting policy due to the existence of many duplicate serial numbers with different weights. Therefore, for these manufacturers the occurrence of a duplicate serial numbers with the same weight is not conclusive proof of itself that we have a duplicate bar, as the serial number may be incorrectly recorded.

As a result, I do not feel that PMR’s "Perfect Internal Duplicate" (identical brand, serial number and weight) rate of 0.0242% for SLV (69 bars out of 285479) is not conclusively proven at this stage. I would note that removing the three manufacturers mentioned above brings this duplication rate down to 11 bars.

One way around the problem of restarted serial numbers, but incomplete recording of year to distinguish duplicated serial numbers for a manufacturer, is (apart from custodians producing a decent/detailed bar list to start with) to look at the frequency of what PMR calls “Rough Internal Duplicates” (identical brand and weight with an almost-identical serial number (eg AB1024 vs 1024). Effectively this is the process of stripping out the year identifier from the serial number so that all serial numbers for that manufacturer are on “equal footing”, so to speak.

PMR makes reference to the technique of removing prefixes in this comment and this comment. But for this to be valid PMR must first prove/establish which manufacturers restart their serial numbers each year and then their serial number/ marking protocol. If for a certain manufacturer the prefix is not a year designator but just part of the sequential serial number, then removing it creates false duplications. It would be the same as removing the first digit from identical weighted bars with serial numbers 1234 and 2234 and concluding they are the same bar.

It is worth noting at this time that the LBMA standards round down actual weights to the nearest 0.10 of a troy ounce. This means that two bars with a reported (bar listing weight) of 1001.1 could actually be two different bars with weights of 1001.11 and 1001.19 when put on scales. This complicates things so lets park this to the side for now.

PMR notes that “To find the same manufacturer with an identical bar weights is not unusual, but beyond some expected statistical occurance it is”. This statement depends on one crucial assumption – the normal distribution of bar weights. As PMR says, “If these exceed what would be predicted by the Gaussian bell curve, one explanation which may be considered is bar ‘cloning’”. I would caution here that normal distributions assume random variables.

Remember that the LBMA standards accept bars with weights between 750 troy ounces and 1100 troy ounces. The reason for this is that is make manufacture of the bars cheaper as one does not have to accurately weigh out granules/shot of silver for each bar – these are industrial wholesale bars after all.

The minimum of 750 is in reality too low and in my experience the distribution of weights is not so wide. One commentator has noted that “there seem to be two categories of weights, one with target weight of 970 oz., the other one 1030 oz”, which does not surprise me. The point I would like to make is that I think a proper statistical analysis of the weight distributions will show that they are not normally distributed and have a material amount of skewness and peaks around certain weights.

To understand why this is the case, consider that pouring bars is much like making cupcakes or muffins. You have standardises moulds in which you pour your cake mixture. One can expect that first time cooks will put too much or too little in, and their resulting muffins are too big or too small. However, over time one builds up skill to the point that we would observe that each muffin is very much the same size.

There is no difference with pouring bars. If you have an experienced pourer, you can expect that they sequence of bars they pour have little variation in weight. You can also expect that some pourers err on the side of underweight bars (too much and the silver may spill on the floor) whereas other more experienced pourers are confident with attempting to fill the mould. If you had an entire sequence of serial numbers, you may also find a group where the bar weights are all over the place – this being when the apprentice pourer had their first go. Wide bar weights could also indicate a workplace where the staff don’t have any pride in their job, so don’t care about accuracy, or maybe where the expected work rate is high so it is not possible to be accurate.

The result is that even within manufacturers their may be significant variances in what constitutes a “normal distribution” of bar weights. I am sure statisticians have ways around this, and PMR needs to get a bit more sophisticated in this regard if it is to make a conclusive case.

Finally, I’d like to make some comments on the three other types of duplicates PMR referred to in their analysis.

Weight Duplicate (brand and weight): Of itself, this is the most useless of the duplicates. Considering the weight variances discussed above, it is inevitable that for any manufacturer over many years of production there will be many duplications of weight. The real use of this is to establish the distribution of weights (histogram) for a manufacturer as a basis against which to check whether an observed frequency of duplicate weights is “normal”.

Internal Duplicate (serial number and brand): Given that some manufacturers restart numbering each year, the lack of a year designator (either as letter prefix or year incorporated into the serial number) means that this duplicate is of no use in proving double counting. It is clear from the Britannia bars (see page 509 of the SLV listing) where there are many occurrences of duplicate serial numbers (but different weights) that the year or year prefix has been left off the bar listing. This use of this duplicate is in determining which manufacturers restart serial numbering and which do not.

Cross Reference Duplicate (brand and serial number on two different ETFs): Again, because we have established that serial numbers are not consistently incorporating the year of manufacture, this duplication is not conclusive proof. For those manufacturers with restarting serial numbers, you also need the addition of weight. I would also note that both lists are not issued at the same time: ETFS bar list is dated 29 July 2009 whereas SLV bar list is dated 24 July 2009, which does allow for the fact that bars redeemed by market makers out of one ETF could have been reallocated to the other ETF (note that both ETFs store their metal in London and allow for sub-custodians, so it is possible that one custodian holds bars for both ETFs).

Comments

Post a Comment